ELECTRO COAGULATION

E-Coagulation treatment of wastewaters is a fast emerging alternative to biological treatment. The significance of this treatment is more emphasized in plants, due to various advantages the process offers.

The Electro Coagulation process is very similar to normal chemical coagulation – the difference is that it uses electrical energy. Both processes aim to destabilize the colloids contained in a quantity of water, but they differ in the method used to add the reagent. In conventional coagulation, the reagent is added as a salt, whereas in electrocoagulation, it is generated from a metal.

E-Coagulation can be defined as an electrochemical process during which the colloidal matter present in a quantity of wastewater is gathered together using compounds resulting from the dissolving of an anode in order to allow the colloids to be separated from the wastewater using conventional techniques. Because they dissolve, the anodes disappear during the course of the treatment, until the moment is reached when they need to be replaced. This means that they are ‘sacrificial anodes’.

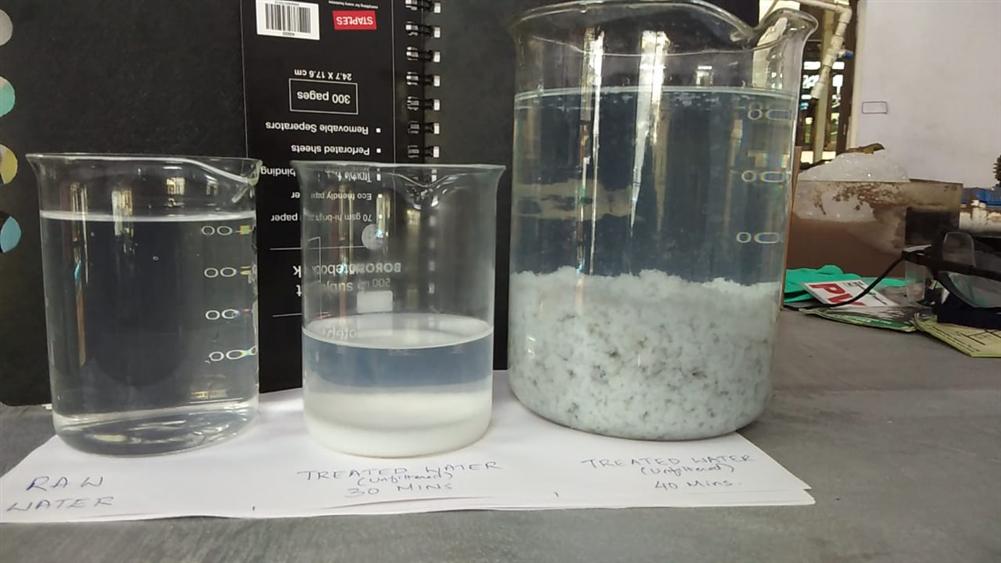

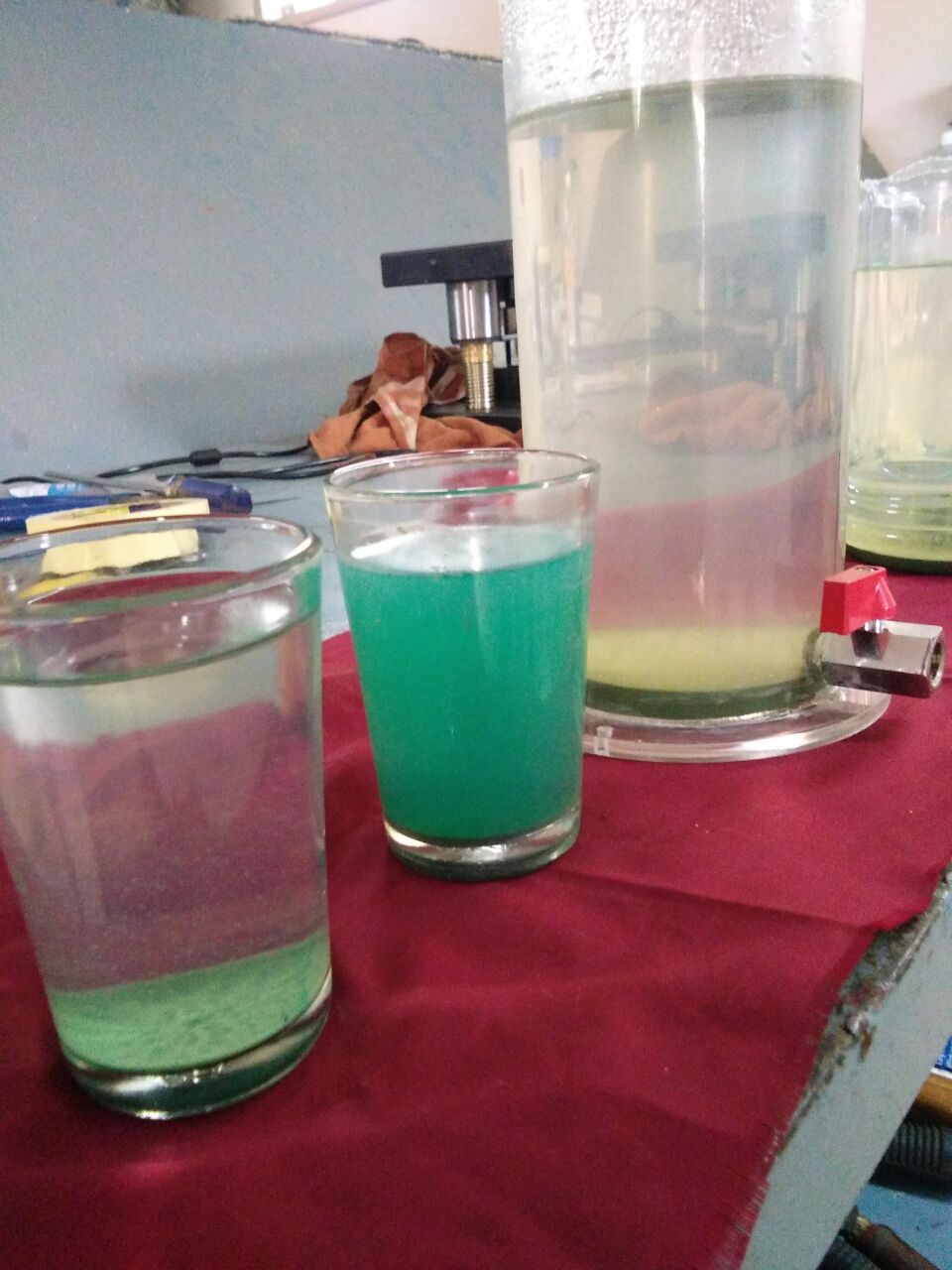

REECON conduct pilot plant testing of the effluent with the prototype unit before starting the project. Attached is the mobile prototype unit for testing of effluent. This result is used to decide for the on the site and off the site parameters of operation of the plant.

Tag words

Electrocoagulation, Effluent Treatment, Colloidal removal, Effluent Recycling

Reecon Aqua Green Technologies Pvt Ltd - Nanotechnology Process, AEWAR- Process Sewage and Effluent treatment Plants, Biogas Plants, Power Management and Solar Electrification, Industrial Automation, Complete solid waste management.

Reecon Aqua Green Technologies PVT. LTD

Ph :+91 9448163002 | Email : info@reeconaqua.in